Heavy Duty Continuous Band Sealer

Price 95000 INR/ Piece

Heavy Duty Continuous Band Sealer Specification

- Type

- Sealing Machines

- Material

- Stainless Steel

- Feature

- Highly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Power

- 230 Watt (w)

- Voltage

- 220 Volt (v)

- Weight (kg)

- 107 Kilograms (kg)

- Dimension (L*W*H)

- 1450 x 680 x 1480 Millimeter (mm)

- Color

- Gray

- Warranty

- 1 Year

Heavy Duty Continuous Band Sealer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 1 Week

About Heavy Duty Continuous Band Sealer

We can customize the Heavy Duty Continuous Band Sealer as per client's requirements. These products are extremely sturdy in nature, with the energy consumption of 230 W, quick speed of sealing, which is 0 to 10 m per min and with the sealing width of 8 to 10 mm. Our Heavy Duty Band Sealer Machine is universally famous for its high quality and performance standards. Located at New Delhi, India, we have a team of experienced professionals, whose aim is to work hard and provide the clients with the best band sealing machine of continuous type. Our expert and dedicated team of engineers, technicians and other allied workers offer after-sales support as well as training to the clients, as a part of our business of service provider. All the business activities are handled under the guidance of our mentors, who have supported us to attain a leading position in the market.

Technical Specification

| Model | SPCS 1100 |

| Voltage (V/Hz) | 220/50 |

| Power (W) | 230 |

| Heat Sealing Power (w) | 300x4 |

| Sealing Speed (m/min) | 0 - 10 |

| Sealing Width (mm) | 8 - 10 |

| Temperature range (Deg.c) | 0 - 300 |

| Distance from the sealing center to the conveying table (mm) | Nil |

| Conveyor size (L x W)mm | 1400x250 |

| Film Thickness (mm) | 0.12 to o.18 |

| Single Conveyor Loading (Kg) | 5 |

| Overall Conveyor Loading (Kg) | 15 |

| Overall Dimension (LxWxH) mm | 1450 x 680 x 1480 |

| Net Weight (Kg) | 107 |

Unparalleled Durability and Performance

Built with stainless steel, this band sealer resists rust and wear, offering exceptional reliability even in demanding environments. Its heavy-duty construction is tailored for high-volume operations, ensuring that the machine meets rigorous industrial standards and offers a long operational life.

Efficient Sealing with Reduced Power Use

Operating at just 230 Watts, the machine efficiently seals packages with minimal electricity usage, making it cost-effective for businesses. The automatic process streamlines operations, reducing labor needs and increasing packaging throughput for various industries.

User-Friendly Automation

The integrated Human Machine Interface simplifies setup and operation, allowing operators to monitor and adjust settings easily. Though not computerized, its advanced controls deliver consistent sealing quality and help maintain production efficiency.

FAQs of Heavy Duty Continuous Band Sealer:

Q: How does the Heavy Duty Continuous Band Sealer operate?

A: This band sealer is automatic and uses an electric drive. Operators place the filled package on the conveyor, where the machine seals it automatically using heat, ensuring airtight and durable closure with minimal human intervention.Q: What materials can be sealed using this machine?

A: The sealer can handle a range of packaging materials, such as polyethylene, polypropylene, and laminated foils, making it versatile for different industries including food, pharmaceutical, and manufacturing sectors.Q: When should I perform routine maintenance on this sealer?

A: Regular maintenance, such as cleaning sealing surfaces and checking for wear and tear, should be done every few weeks, depending on usage. This ensures optimal performance and longevity, and minor adjustments can often be handled in-house.Q: Where is this sealing machine typically used?

A: This machine is ideal for use in large-scale production facilities, distribution centers, and industrial packaging lines across various sectors in India. Its heavy-duty build supports high-throughput sealing requirements.Q: What is involved in the sealing process with this machine?

A: The process involves placing products on the conveyor belt, where the package passes through the heated sealing mechanism; the seam is pressed securely, and the sealed product continues out on the conveyor, ready for shipment or further processing.Q: How can businesses benefit from using this machine?

A: Businesses benefit from speedier, uniform sealing, reduced operational costs due to low power consumption, and decreased risk of product contamination. Its durability and rust-resistant construction lead to consistently high performance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Machine Category

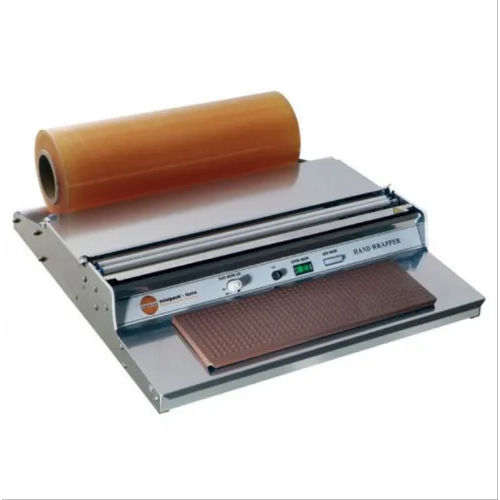

Cling Film Wrapping Sealer

Minimum Order Quantity : 1 Unit

Voltage : AC 220/50 Volt (v)

Type : Other, Cling Film Wrapping Sealer

Power : 450 Watt (w)

Color : Silver

Dimension (L*W*H) : 610 570 120 Millimeter (mm)

Hand Operated Sealing Machine

Minimum Order Quantity : 1 Piece

Voltage : 240 Volt (v)

Type : Sealing Machines

Color : Other, Red & Gray

Hand Operated Sealing Machine

Minimum Order Quantity : 1 Unit

Voltage : 200/50 Volt (v)

Type : Other, Hand Operated Sealing Machine

Power : 260 Watt (w)

Color : White

Dimension (L*W*H) : 325*80*225 Millimeter (mm)

Heavy Duty Continuous Band Sealer

Minimum Order Quantity : 1 Unit

Voltage : 220/50 Volt (v)

Type : Other, Heavy Duty Continuous Band Sealer

Power : 230 Watt (w)

Color : Silver

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free