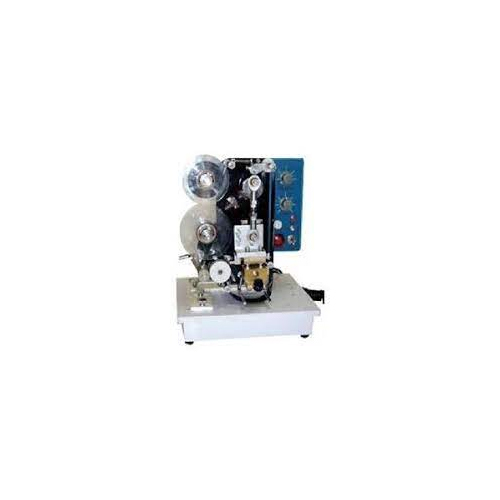

Motorized Ribbon Hot Batch Coding Machine

Motorized Ribbon Hot Batch Coding Machine Specification

- Type

- Motorized Ribbon Hot Batch Coding Machine

- Material

- MS ( Body )

- Feature

- Highly Efficient

- Capacity

- 16 Pcs/min

- Automatic Grade

- Semi-Automatic

- Drive Type

- Electric

- Power

- 60 Watt (w)

- Voltage

- 220-240 V Volt (v)

- Weight (kg)

- 6 Kilograms (kg)

- Dimension (L*W*H)

- 355x340x525mm Millimeter (mm)

Motorized Ribbon Hot Batch Coding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Motorized Ribbon Hot Batch Coding Machine

Specification

| MAKE | unipack packaging solution |

| Model | ups -motorized 4line |

| Material | MS ( Body ) |

| Automation Grade | Semi-Automatic |

| Capacity | 16 pieces per min |

| Voltage | 220-240 V |

| Frequency | 50-60 Hz |

| Power Source | Electric |

| Phase | single phase |

| Wattage | 60 Watt |

| Machine size | 355x340x525mm |

| weight | 6kg |

Exceptional Efficiency and Reliability

Engineered for performance, our motorized ribbon hot batch coding machine guarantees productivity with a 16 pcs/min output. The semi-automatic operation and robust electric drive ensure consistent coding, reducing manual labor and enhancing workplace efficiency. Its sturdy MS body withstands rigorous daily use, making it perfect for busy manufacturing and packaging environments.

Compact Design and Easy Operation

Despite its strong build, the machine remains lightweight and compact, with a total weight of just 6 kg and measurements of 355x340x525mm. This allows for straightforward installation even in space-constrained production lines. The user-friendly interface and semi-automatic grade make it simple to operate and maintain, ensuring smooth workflows.

FAQs of Motorized Ribbon Hot Batch Coding Machine:

Q: How does the motorized ribbon hot batch coding machine work?

A: The machine operates by using an electric-driven mechanism to transfer ribbon ink onto packaging materials. When the product passes through, it accurately imprints batch codes, manufacturing dates, or other essential information onto the package surface.Q: What are the key benefits of using this coding machine?

A: Its main advantages include high efficiency (16 pcs/min), consistent print quality, semi-automatic operation for labor savings, and reliable performance owing to its sturdy MS body. The compact size also allows easy placement in various production setups.Q: When should I consider using this machine in my production process?

A: This machine is ideal for businesses with medium to high batch coding requirements, particularly when efficiency and reliable imprinting are crucial. Consider integrating it when manual coding becomes time-consuming or when higher output and accuracy are essential.Q: Where is the motorized ribbon hot batch coding machine typically used?

A: It is commonly employed in industrial sectors such as food packaging, pharmaceuticals, cosmetics, and manufacturing units where batch coding on various packaging materials is a requirement. Its compact design suits both small workshops and larger factory settings.Q: What is the process for operating and maintaining this machine?

A: Operating the machine involves loading the ribbon ink, setting up the desired coding parameters, and feeding the packaging material. Routine maintenance includes cleaning the ribbon area and periodically checking the electric components to ensure optimal performance.Q: How can this machine enhance my business operations?

A: By automating and accelerating the batch coding process, it reduces manual labor, minimizes errors, and ensures your products comply with labeling regulations. This ultimately boosts productivity and the professional appeal of your products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Batch Coder Category

Manual Coding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx. 220mm x 160mm x 140mm

Power : No Power Required

Type : Other, Manual Coding Machine

Color : Other, Black (Blue Red Optional)

Pad Printing Machine

Price 80000 INR / Piece

Minimum Order Quantity : 1 Pack

Dimension (L*W*H) : 435x405x560 Millimeter (mm)

Power : 180 Watt (w)

Type : Other, Pad Printing Machine

Color : Other, Red & Black

Dry Ink Batch Coder

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 440x465x300 Millimeter (mm)

Power : 180 Watt (w)

Type : Coding Machines

Color : Other

Pad Printing Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 435x405x560 Millimeter (mm)

Power : 180 Watt (w)

Type : Other, Pad Printing Machine

Color : Other, Red

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS