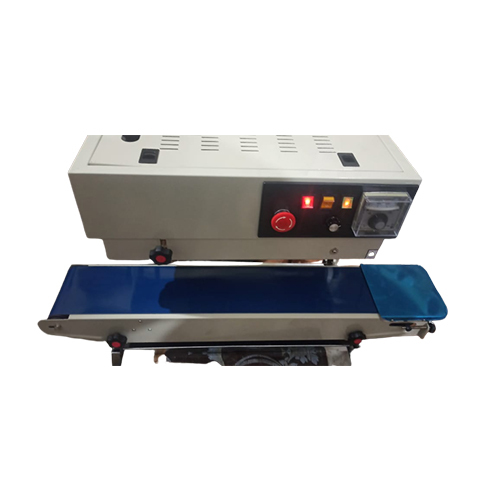

10 Kg Vertical Band Sealer

10 Kg Vertical Band Sealer Specification

- Type

- 10 Kg Vertical Band Sealer

- Power

- 1235 W Watt (w)

- Voltage

- 110V/220V Volt (v)

- Weight (kg)

- 70 Kilograms (kg)

- Dimension (L*W*H)

- 1243*580*1228 (LXWXH)(MM) Millimeter (mm)

- Color

- White

10 Kg Vertical Band Sealer Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 10 Kg Vertical Band Sealer

Specification

| MAKE | unipack packaging solution |

| Automation Grade Semi-Automatic | Packaging Type Pouch |

| Power | 1235 W |

| Operational Mode Vertical Material | Mild Steel Model |

| Model Name/Number | FOR 10 KG BAND SEALER |

| CAPACITY | 10 KG |

| Max. Conveyor Load | 10 KG ORIENTATION VERTICAL |

| FREQUENCY | 50-60 Hz |

| TEMPERATURE | 0-300 DEG.C |

| VOLTAGE | 110V/220V |

| WEIGHT | 70 KG |

| SEALING SPEED | 6-12 MM |

| SIZE | 1243*580*1228 (LXWXH)(MM) |

Effortless Heavy-Duty Sealing

Designed for bulk packaging needs, this vertical band sealer handles up to 10 kg bags with ease. Its advanced mechanism and solid frame ensure consistent and leak-proof seals, making it indispensable for industries ranging from food processing to chemical manufacturing. Operate it on both 110V and 220V supplies, aligning seamlessly with diverse facility setups in India.

Versatile Power and User-Friendly Design

With a dual-voltage system and powerful 1235W motor, the sealer fits into various industrial environments. The machines straightforward controls and ergonomic vertical design simplify usage, minimizing the learning curve for new operators. Its impressive footprint allows for easy integration into any production line or packaging area.

FAQs of 10 Kg Vertical Band Sealer:

Q: How is the 10 Kg Vertical Band Sealer operated?

A: To operate the 10 Kg Vertical Band Sealer, connect the machine to a suitable power source (110V or 220V), adjust the settings for your bags thickness, feed the filled bag vertically through the sealing mechanism, and start the sealing process. The conveyor automatically moves the bag, providing a secure, professional seal.Q: What types of materials can this vertical band sealer handle?

A: This sealer is compatible with a broad spectrum of bag materials, including polyethylene, polypropylene, laminated films, and other commonly used industrial packaging substrates, accommodating bags weighing up to 10 kilograms.Q: When should I use this band sealer in my production process?

A: The vertical band sealer should be used after your products are packed and ready for sealing. It is ideal for finalizing packaging before storage, shipment, or display, especially for bulk goods needing strong, tamper-proof closures.Q: Where can this sealer be installed within my facility?

A: You can place the 10 Kg Vertical Band Sealer in any packaging area equipped with either 110V or 220V power supply. Its vertical structure optimizes workspace and suits diverse production environments, from packaging rooms to warehouse lines.Q: What is the sealing process of this band sealer?

A: The process involves loading a filled bag onto the conveyor, which then moves it vertically past heating elements that seal the bags opening. The control panel lets users modify speed and temperature to obtain optimal results on different materials.Q: Why is this 10 Kg band sealer beneficial for bulk packaging operations?

A: Its capacity to reliably seal heavy bags improves efficiency, reduces manual labor, and prevents leakage or contamination, resulting in enhanced product safety and faster workflow for distributors, exporters, and manufacturers alike.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Band Sealer Category

1000 Band Sealer

Minimum Order Quantity : 1 Unit

Power : 1000 Watt (w)

Type : Other, Band Sealer

Color : White

Vertical Band Sealer Machine

Minimum Order Quantity : 1 Unit

Power : 650 Watt (w)

Type : Other, Vertical Band Sealer Machine

Color : White

Voltage : 220/50 Volt (v)

Dimension (L*W*H) : 840 x 380 x 550 Millimeter (mm)

770 Nitrogen Flushing Continuous Band Sealer

Minimum Order Quantity : 1 Unit

Power : 220V Volt (v)

Type : Other, Nitrogen Flushing Continuous Band Sealer

Voltage : 110/220V/5060Hz Volt (v)

Dimension (L*W*H) : 840 x 380 x 320 Millimeter (mm)

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free