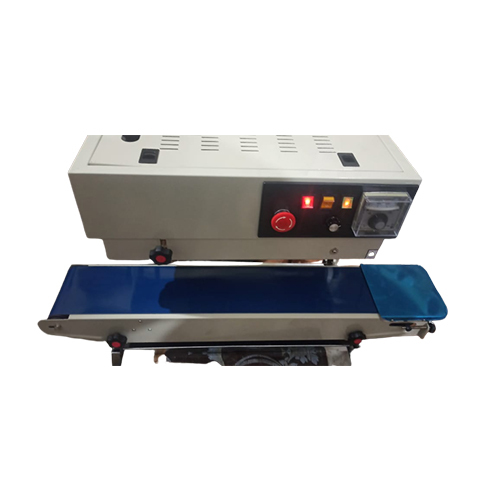

770 Nitrogen Flushing Continuous Band Sealer

770 Nitrogen Flushing Continuous Band Sealer Specification

- Type

- Nitrogen Flushing Continuous Band Sealer

- Power

- 220V Volt (v)

- Voltage

- 110/220V/50-60Hz Volt (v)

- Weight (kg)

- 35 Kilograms (kg)

- Dimension (L*W*H)

- 840 x 380 x 320 Millimeter (mm)

770 Nitrogen Flushing Continuous Band Sealer Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About 770 Nitrogen Flushing Continuous Band Sealer

Specification

| Make | unipack packaging solution |

| Model | UPS-770 |

| Automation Grade | Semi-Automatic |

| Max. Conveyor Load | 5 to 9 Mtr Per Mtr |

| Temperature | 300c |

| Power | 220V |

| Sealing Speed | 25 30 Poch per Mint |

| Sealing Type | 12mm hot bar |

| Capacity | 1kg-3kg |

| Sealing width | 8 -12 mm |

| Voltage | 110/220V/50-60Hz |

| Sealing Speed (m/min) | 0 ~ 12 (0 ~ 16) |

| Distance from the sealing center to the conveying table (mm) | 10 ~ 40 |

| Convenor size ( L x W )mm | 840 x 153 |

| Film Thickness (mm) | 0.08 |

| Single Conveyor Loading (Kg) | 1 |

| Overall Dimension (LxWxH)mm | 840 x 380 x 320 |

| Net Weight (Kg) | 35 |

Advanced Nitrogen Flushing System

Protect your products against oxidation and spoilage with the 770 Band Sealers integrated nitrogen flushing feature. By replacing oxygen in the packaging with inert nitrogen gas, it helps keep products fresh and extends their shelf life, making it an optimal choice for sensitive goods such as snacks, spices, and pharmaceuticals.

Precision Engineering and Versatile Power Options

Designed for adaptability, the sealer supports both 110V and 220V power inputs with 50-60Hz frequency. This versatility allows seamless integration into various production lines and ensures consistent, reliable sealing performance, catering to diverse industry requirements.

FAQs of 770 Nitrogen Flushing Continuous Band Sealer:

Q: How does the nitrogen flushing function enhance packaging with the 770 Continuous Band Sealer?

A: The nitrogen flushing system eliminates oxygen inside the package before sealing, thereby reducing product oxidation and increasing shelf life. This is especially beneficial for perishable goods, electronics, and pharmaceutical items.Q: What types of materials and products can be sealed with this machine?

A: The sealer is compatible with various heat sealable materials, such as laminated films, aluminum foil, and polyethylene bags, making it ideal for food, pharmaceutical, and light industrial packaging.Q: When is nitrogen flushing particularly beneficial during the packaging process?

A: Nitrogen flushing should be used when packaging products susceptible to degradation from oxygen exposure, such as snacks, dry fruits, coffee, or medical supplies, to maintain freshness and minimize spoilage.Q: Where can this nitrogen flushing band sealer be used?

A: This machine is suitable for use in factories, food processing units, pharmaceutical production, and packaging lines, especially where product preservation and long shelf life are essential.Q: What is the process for operating this nitrogen flushing band sealer?

A: Operation involves setting the appropriate temperature and speed, placing the package on the moving conveyor, and allowing nitrogen to displace the air in the bag before the robust band sealer creates a secure, airtight seal.Q: What are the main benefits of using this band sealer for industrial packaging?

A: Key benefits include extended shelf life, improved product protection from oxidation and moisture, efficient continuous sealing, versatile voltage compatibility, and suitability for a wide range of bag sizes and materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Band Sealer Category

1000 Band Sealer

Minimum Order Quantity : 1 Unit

Color : White

Power : 1000 Watt (w)

Type : Other, Band Sealer

10 Kg Vertical Band Sealer

Minimum Order Quantity : 1 Unit

Color : White

Power : 1235 W Watt (w)

Type : Other, 10 Kg Vertical Band Sealer

Voltage : 110V/220V Volt (v)

Dimension (L*W*H) : 1243*580*1228 (LXWXH)(MM) Millimeter (mm)

Vertical Band Sealer Machine

Minimum Order Quantity : 1 Unit

Color : White

Power : 650 Watt (w)

Type : Other, Vertical Band Sealer Machine

Voltage : 220/50 Volt (v)

Dimension (L*W*H) : 840 x 380 x 550 Millimeter (mm)

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS