Air Flushing Continuous Band Sealer

Air Flushing Continuous Band Sealer Specification

- Type

- Air Flushing Continuous Band Sealer

- Power

- 835 Watt (w)

- Voltage

- 220/50 Volt (v)

- Weight (kg)

- 62 Kilograms (kg)

- Dimension (L*W*H)

- 1050 x 560 x 900 Millimeter (mm)

Air Flushing Continuous Band Sealer Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Air Flushing Continuous Band Sealer

Technical Specifications:

Model | SPCS 900AF (Air Flushing) |

Voltage (V/Hz) | 220/50 |

Power (W) | 835 |

Heat Sealing Power (w) | 40x2 |

Sealing Speed (m/min) | 0 to 12 (0 to 16) |

Sealing Width (mm) | 8 to 10 |

Temperature range (oC) | 0 to 300 |

Distance from the sealing center to the conveying table (mm) | 10 to 40 |

Conveyor size (L x W)mm | 930x180 |

Film Thickness (mm) | 0.08 |

Single Conveyor Loading (Kg) | 1 |

Overall Conveyor Loading (Kg) | 3 |

Overall Dimension (LxWxH) mm | 1050 x 560 x 900 |

Net Weight (Kg) | 62 |

Advanced Sealing Mechanism

The Air Flushing Continuous Band Sealer employs a unique air-flushing process, removing excess air from packaging before sealing. This results in longer shelf life for products and enhances overall packaging presentation. Its continuous operation is tailored for streamlining bulk packaging tasks.

Sturdy Build and Easy Operation

With its dimensions of 1050 x 560 x 900 mm and a weight of 62 kg, this band sealer boasts a durable construction for consistent daily use. The user-friendly controls and adjustable settings make the machine accessible for a wide range of operators, minimizing training time and maximizing productivity.

FAQs of Air Flushing Continuous Band Sealer:

Q: How does the Air Flushing Continuous Band Sealer work?

A: This band sealer uses air-flushing technology to remove excess air from packaging before sealing. The continuous band mechanism then creates an airtight seal, ensuring product preservation and protection.Q: What types of products can I seal with this machine?

A: The sealer is ideal for packaging various food items, pharmaceuticals, hardware, and electronic components. It is especially beneficial for products requiring extended shelf life through air removal.Q: When should I use an air flushing band sealer instead of a regular sealer?

A: Choose an air flushing band sealer when packaging items that benefit from reduced oxygen exposure, such as perishable foods or sensitive products, to maintain freshness and prevent spoilage.Q: Where can this machine be installed or used?

A: This machine is suitable for use in packaging units, factories, warehouses, or export facilities. Its compact size allows for flexible placement in both small and larger production spaces.Q: What is the installation process for this band sealer?

A: Installation involves placing the sealer on a stable surface, connecting it to a 220/50 volt power supply, and adjusting the settings as needed for your packaging materials. It can be easily set up and integrated into existing production lines.Q: How do I maintain and clean the Air Flushing Continuous Band Sealer?

A: Regularly clean the sealing belts and ensure that the air flushing system is free from obstructions. Periodic checks of electrical components and timely servicing will help maintain optimal performance and longevity.Q: What are the benefits of using this continuous band sealer?

A: The key benefits include improved preservation of products, higher packaging speed, reduced manual labor, and enhanced presentation quality. Its air flushing feature is particularly advantageous for exporters and manufacturers aiming for superior product protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Machine Category

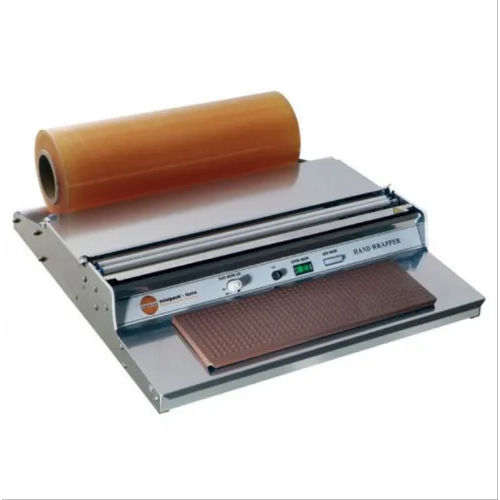

Cling Film Wrapping Sealer

Minimum Order Quantity : 1 Unit

Type : Other, Cling Film Wrapping Sealer

Voltage : AC 220/50 Volt (v)

Power : 450 Watt (w)

Dimension (L*W*H) : 610 570 120 Millimeter (mm)

Air Flushing Continuous Band Sealer

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Sealing Machines

Voltage : 220 Volt (v)

Power : 835 Watt (w)

Dimension (L*W*H) : 1050 x 560 x 900 Millimeter (mm)

Heavy Duty Continuous Band Sealer

Price 95000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Sealing Machines

Voltage : 220 Volt (v)

Power : 230 Watt (w)

Dimension (L*W*H) : 1450 x 680 x 1480 Millimeter (mm)

Hand Operated Sealing Machine

Minimum Order Quantity : 1 Unit

Type : Other, Hand Operated Sealing Machine

Voltage : 200/50 Volt (v)

Power : 260 Watt (w)

Dimension (L*W*H) : 325*80*225 Millimeter (mm)

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free