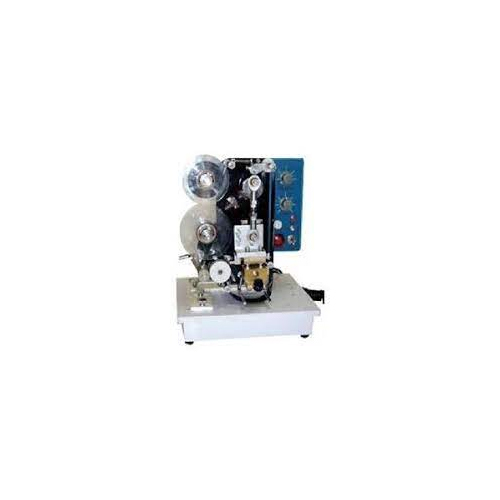

Dry Ink Batch Coder

Dry Ink Batch Coder Specification

- Type

- Dry Ink Batch Coder

- Material

- Stainless steel

- Power

- 180 Watt (w)

- Voltage

- 220/50 Volt (v)

- Dimension (L*W*H)

- 440x465x300 Millimeter (mm)

- Color

- Silver

Dry Ink Batch Coder Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Dry Ink Batch Coder

Technical Specifications:

Model | SPCS 600 |

Voltage (V/Hz) | 220/50 |

Power (W) | 180 |

Printing Speed (w) | 100 |

Object size (mm) | L 50 to 500 W 30 to 300 |

Printing type | Solid link coding |

Dimension (LxWxH)(mm) | 440x465x300 |

Net Weight (Kg) | 26 |

Stainless Steel Durability

Constructed from high-quality stainless steel, the Dry Ink Batch Coder resists corrosion and ensures long-term operational reliability, even in demanding industrial settings. Its robust build supports frequent use, maintaining consistent performance throughout extended production cycles.

Effortless Operation & Integration

Featuring user-friendly controls and a compact design, this batch coder is easy to install alongside packaging lines. Its standard voltage and manageable power requirements simplify integration without complex electrical modifications.

FAQs of Dry Ink Batch Coder:

Q: How does the Dry Ink Batch Coder work?

A: The Dry Ink Batch Coder utilizes a heated ink roller to transfer quick-drying ink onto packaging surfaces, providing clear batch details. By feeding packaging materials through the unit, precise codes are printed efficiently and reliably.Q: What materials can be coded using this machine?

A: This batch coder is compatible with a variety of packaging substrates such as laminated pouches, films, and labels, making it suitable for food, pharmaceuticals, cosmetics, and other industries.Q: When should this batch coder be used in the production process?

A: The machine is designed for use after product packaging but prior to final sealing, ensuring batch codes are applied before distribution or storage.Q: Where can the Dry Ink Batch Coder be installed?

A: Thanks to its compact design (440x465x300 mm), the coder can be integrated into existing production lines or used as a stand-alone unit in manufacturing facilities, warehouses, or packaging plants.Q: What is the process for setting up and operating the machine?

A: Simply connect the machine to a standard 220/50 Volt power source, load the necessary ink roller, adjust the print settings, and feed your packaging materials for instant and accurate batch coding.Q: How is the Dry Ink Batch Coder beneficial to businesses?

A: It provides fast, consistent, and legible batch or date coding, which supports regulatory compliance and product traceability, all while reducing manual labor and minimizing coding errors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Batch Coder Category

Manual Coding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx. 220mm x 160mm x 140mm

Power : No Power Required

Type : Other, Manual Coding Machine

Weight (kg) : 2.4 Kilograms (kg)

Dry Ink Batch Coder

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 440x465x300 Millimeter (mm)

Power : 180 Watt (w)

Type : Coding Machines

Weight (kg) : 26 Kilograms (kg)

Pad Printing Machine

Price 80000 INR / Piece

Minimum Order Quantity : 1 Pack

Dimension (L*W*H) : 435x405x560 Millimeter (mm)

Power : 180 Watt (w)

Type : Other, Pad Printing Machine

Weight (kg) : 21 Kilograms (kg)

Motorized Ribbon Hot Batch Coding Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 355x340x525mm Millimeter (mm)

Power : 60 Watt (w)

Type : Other, Motorized Ribbon Hot Batch Coding Machine

Weight (kg) : 6 Kilograms (kg)

We are a leading Sevana Dealer in Delhi / NCR.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free